Fresh Frozen Cannabis - Quick Guide for Canadian Licensed Cultivators

by Jason Tobias, July 28, 2021

Freezing cannabis immediately after harvest is an increasingly common alternative to drying. Freezing retains the unique terpenes and flavinoids of the plant without the cost and time of traditional drying and curing methods.

Fresh frozen cannabis makes live rosin, hash rosin, live resin, or distillate for edibles, topicals and tinctures.

For outdoor growers, freezing is also an opportunity to avoid the crop-tober supply glut and sell at higher prices.

Other advantages of fresh frozen compared to traditional drying include:

Faster - hours to freeze vs days to dry

Lower labour inputs and less handling of the plant

Uses less square footage

Simplified temperature and humidity control

Lower risk of mold and fungus growth

Longer storage life and less product degradation in storage

In this article we discuss:

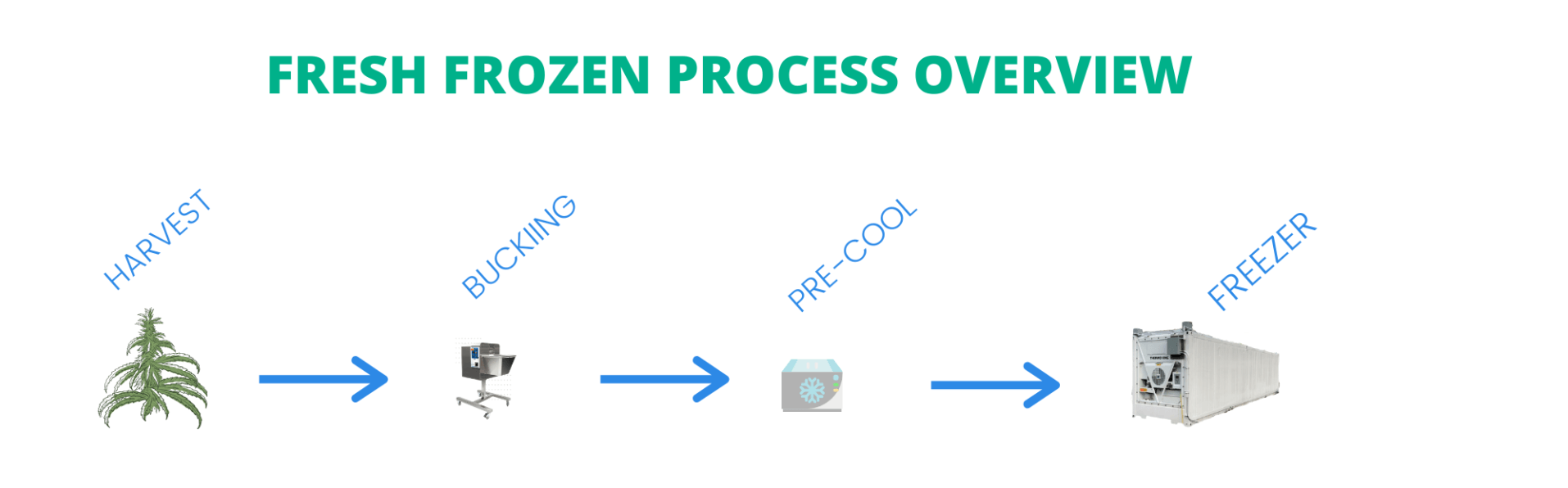

Fresh Frozen Process Overview

Site Planning and Regulatory Compliance

Need help getting setup for fresh frozen? Call us, we can help. Consultations are always free and confidential.

Process Overview

Harvest

Harvest the cannabis plants and separate the stems, branches and leaves from the flower. Flower can be either bulk packaged or placed in trays for pre-freezing.

Tips:

Plan the harvest in advance including any required tools and equipment

Use an assembly line process to reduce staff movement and labour

Preserve terpenes by working in cooler temperatures at night or early morning

Use equipment to speed up harvest and reduce labour

Pre-Cooling / Pre-Freezing

Pre-cooling/Pre-Freezing the flower before placing it in cold storage will speed the freezing process, and improve the efficiency of the storage freezer. Freezing quickly not only minimizes terpene loss and product degradation, it also reduces the amount of water vapour frozen with the plant.

Pre-cooling can be accomplished using cryogenics (liquid nitrogen or liquid carbon dioxide), mechanical freezers or dry ice. A cryogenic freezing tunnel is efficient and effective for significant product volumes. For smaller harvests batching in mechanical freezers or coolers is more typical.

Flower can be bagged before or after the pre-cooling step. Freezing loose flower in trays increases the handling but also allows for a “shake trim” to knock off frozen leaves before bagging. Freezing ambient temperature flower in bags can result in frozen bricks which will have to be milled or bashed apart for extraction.

Freezing

Once the flower is ready for the freezer, it is a good idea to load in batches. Warm ambient air carries a lot of moisture which will in turn form ice and increase the energy consumption of the freezer. For this reason freezers designed for storage will not perform optimally with the doors open.

Reefer containers loaded with fresh harvested product will work hard to cool 2,000 kg to -20 °C in ~12 hours. Freezing time is reduced for pre-cooled or cryogenically frozen cannabis going into the freezer.

Site Planning and Regulatory Compliance

Site Plan

Budget enough space within the site perimeter for freezers and all the associated harvest activities.

When packaged in bulk, 160 sq. ft. will accommodate roughly 1 acre of bucked crop. In other words 2,000 kg per 40’ reefer container.

Don’t forget space for trucks, staff movement, and the harvesting and pre-cooling steps.

Electrical

A standard 100amp electrical service isn’t enough power for large scale freezing.

The amount of power required will depend on your equipment but 5 - 10kVA of electrical load per acre of bucked crop can be expected.

Utility upgrades may be expensive, slow or unavailable depending on your location so generators are often used instead.

Harvest Activities within Operations (Cultivation) Areas

Whether outdoor or indoor, cannabis can be prepared for freezing in the cultivation area with no licence amendments.

The freezer itself is classified as a storage area. Adding a new freezer to an existing site requires a

licence amendment and prior approval from Health Canada. This amendment process takes time and requires the submission of an evidence package to show compliance with all the regulations, including physical security.

In some limited cases, temporary storage in refrigerated cube vans or trailers is “in transport” and therefore subject to different requirements. In general, if the freezer is on your site plan or will be on your site for any period of time once loaded it becomes more difficult to argue that the product is in transport. We don’t recommend playing fast and loose with this one.

Ironically, odour control is another factor that must be addressed even if the airtight freezer is in the middle of a field of outdoor grown cannabis. Generally the addition of a carbon filtration unit inside the freezer is enough to tick the box on this requirement.

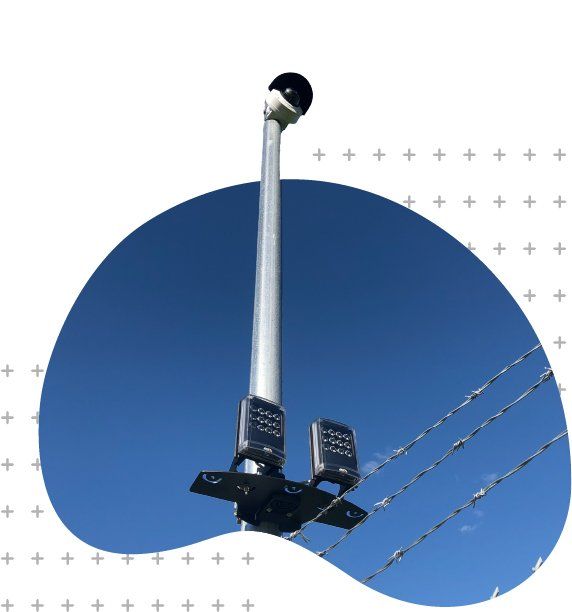

Physical Security

The physical security requirements for storage areas are discussed in this post.

Commercial grade cameras and intrusion detection devices rated for low-temperature outdoor use will be suitable for use in a freezer. Make sure that devices are sealed against moisture ingress and provision cameras with built-in heaters to reduce lens fogging.

While digital card readers are a great way to track access to the freezer. However, standard mag locks and electric strikes become fouled by ice overtime which will prevent them from working properly. Card readers for record retention paired with manual locks can be a good compromise.

Ready to start? Otm Systems offers a variety of solutions for flash frozen flower.

Book a call with Jason for a free consultation about your cannabis project.

/ CONTACT

Let's talk, meet,

work together.

Send us an email.

Let's Connect:

New Paragraph

All Rights Reserved | Otm Systems Ltd. | BC Security Licence B6543 | BC Contractor LEL0209876

Privacy Policy | Terms | Disclaimer